With a standard vacuum pump designed specifically for evacuation and dehydration at the forefront, this discussion delves into the intricacies of these pumps, exploring their unique features, applications, and technical considerations. From understanding their operating principles to navigating the competitive market landscape, this comprehensive overview provides valuable insights into the world of vacuum pumps.

Vacuum pumps play a crucial role in various industrial and scientific processes, and their ability to evacuate gases and dehydrate materials makes them indispensable for applications ranging from freeze drying to vacuum packaging. This discussion will delve into the specific design considerations for vacuum pumps intended for evacuation and dehydration, highlighting their advantages and limitations.

1. Vacuum Pump Overview

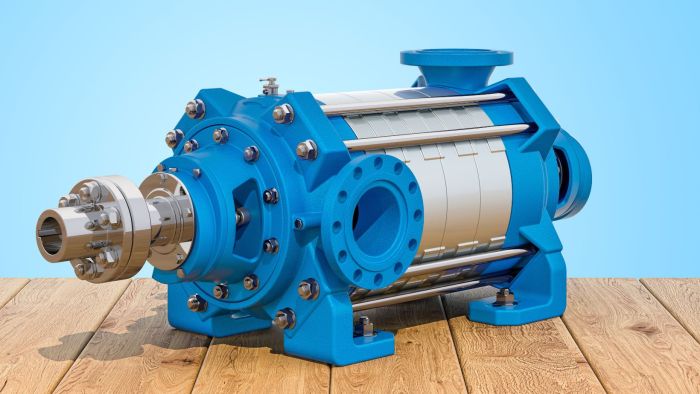

A standard vacuum pump is a device designed to evacuate gases and create a vacuum within a closed chamber or system. It operates on the principle of reducing the pressure inside the chamber by removing gas molecules through a mechanical or chemical process.

Vacuum pumps are widely used in various industrial and scientific applications, including:

- Evacuating air from sealed containers

- Dehydrating materials

- Creating and maintaining vacuum environments for experiments and processes

Types of Standard Vacuum Pumps

There are several types of standard vacuum pumps, each with its own unique mechanism and characteristics:

- Mechanical pumps: Use mechanical components, such as pistons or vanes, to create a vacuum by compressing and expelling gas molecules.

- Chemical pumps: Utilize chemical reactions to absorb or react with gas molecules, creating a vacuum.

- Diffusion pumps: Employ a high-velocity jet of vapor to create a vacuum by transferring momentum to gas molecules.

- Cryogenic pumps: Use extremely low temperatures to condense and trap gas molecules, creating a vacuum.

2. Evacuation and Dehydration Applications: A Standard Vacuum Pump Designed Specifically For Evacuation And Dehydration

Standard vacuum pumps designed specifically for evacuation and dehydration applications have certain design features that enhance their performance in these tasks.

Evacuation

For evacuation applications, vacuum pumps are used to remove air or other gases from a closed chamber or system. This is often necessary to create a vacuum environment for processes such as:

- Packaging and storage of products that require a vacuum

- Evacuating air from refrigeration and air conditioning systems

- Degasifying materials to remove trapped gases

Dehydration

Vacuum pumps are also used for dehydration applications, where the goal is to remove moisture from a material. This can be achieved by creating a vacuum environment that draws out moisture through evaporation.

Vacuum dehydration is commonly used in industries such as:

- Pharmaceutical manufacturing

- Food processing

- Chemical synthesis

The benefits of using standard vacuum pumps for evacuation and dehydration applications include:

- Efficient removal of gases and moisture

- Ability to create high vacuum levels

- Compact and portable design

3. Technical Specifications

When selecting a standard vacuum pump for evacuation and dehydration applications, it is important to consider the following technical specifications:

Flow Rate

The flow rate of a vacuum pump is measured in cubic feet per minute (CFM) or cubic meters per hour (m3/h) and indicates the volume of gas that the pump can evacuate per unit time.

Vacuum Level

The vacuum level is measured in units of Torr, millibars (mbar), or Pascals (Pa) and indicates the lowest pressure that the pump can achieve.

Power Consumption

The power consumption of a vacuum pump is measured in watts (W) and indicates the amount of electrical power required to operate the pump.

Other Specifications, A standard vacuum pump designed specifically for evacuation and dehydration

In addition to these key specifications, other factors to consider include:

- Inlet and outlet connections

- Noise level

- Duty cycle

- Operating temperature range

4. Operation and Maintenance

Proper operation and maintenance are essential to ensure the optimal performance and longevity of a standard vacuum pump.

Operation

Before operating a vacuum pump, it is important to:

- Read and understand the manufacturer’s instructions

- Ensure that the pump is properly connected to the system

- Check the oil level and replace if necessary

Maintenance

Regular maintenance is crucial to prevent breakdowns and extend the life of the vacuum pump. This includes:

- Changing the oil at regular intervals

- Cleaning or replacing filters

- Inspecting seals and gaskets for leaks

- Performing preventive maintenance checks as recommended by the manufacturer

Troubleshooting

Common troubleshooting procedures for vacuum pumps include:

- Checking for leaks

- Inspecting the oil level

- Verifying the power supply

- Contacting the manufacturer for technical support

5. Market Overview

The market for standard vacuum pumps is highly competitive, with numerous manufacturers and suppliers offering a wide range of products.

Major Manufacturers

Some of the major manufacturers of standard vacuum pumps include:

- Busch Vacuum Solutions

- Edwards Vacuum

- Pfeiffer Vacuum

- Leybold

Competitive Landscape

The competitive landscape is characterized by ongoing innovation and technological advancements. Manufacturers are focusing on developing more efficient, reliable, and environmentally friendly vacuum pumps.

Market Trends

Key market trends include:

- Growing demand for vacuum pumps in emerging economies

- Increasing adoption of vacuum pumps in new applications, such as renewable energy and medical devices

- Emphasis on energy efficiency and sustainability

FAQ Insights

What are the key technical specifications to consider when selecting a vacuum pump for evacuation and dehydration?

Flow rate, vacuum level, power consumption, and ultimate pressure are crucial factors to consider when selecting a vacuum pump for evacuation and dehydration.

What are the benefits of using a standard vacuum pump for evacuation and dehydration?

Standard vacuum pumps offer advantages such as reliability, cost-effectiveness, and ease of maintenance, making them suitable for various applications.

What are the limitations of using a standard vacuum pump for evacuation and dehydration?

Standard vacuum pumps may have limitations in terms of ultimate vacuum level, flow rate, and compatibility with certain materials.